key words:low flow progressing cavity pump, low flow progressive cavity pumps,low volume progressive cavity pumps

A progressing cavity pump is a type of positive displacement pump and is also known as a progressive cavity pump, progg cavity pump, eccentric screw pump or cavity pump. It transfers fluid by means of the progress, through the pump, of a sequence of small, fixed shape, discrete cavities, as its rotor is turned. This leads to the volumetric flow rate being proportional to the rotation rate (bidirectionally) and to low levels of shearing being applied to the pumped fluid.

These low flow progressive cavity pump have application in fluid metering and pumping of viscous or shear-sensitive materials. The cavities taper down toward their ends and overlap. As one cavity diminishes another increases, the net flow amount has minimal variation as the total displacement is equal. This design results in a flow with little to no pulse.

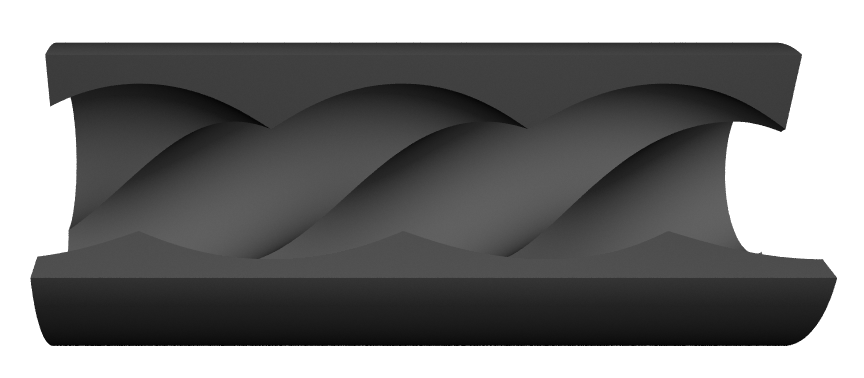

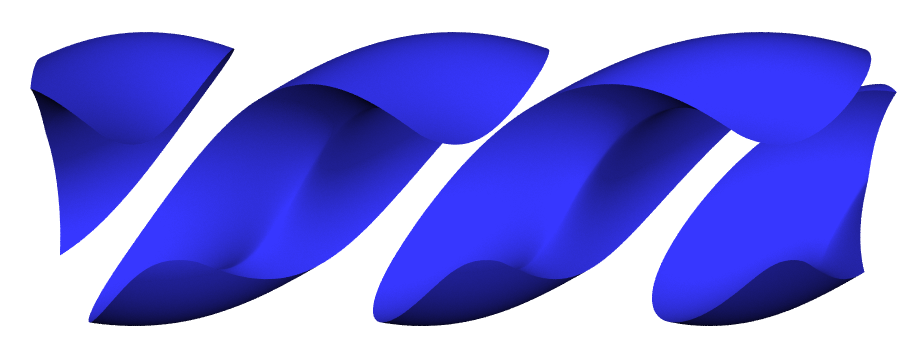

The progressing cavity pump normally consists of a helical rotor and a twin helix, twice the wavelength helical hole in a stator. The rotor seals tightly against the stator as it rotates, forming a set of fixed-size cavities in between. The cavities move when the rotor is rotated but their shape or volume does not change. The pumped material is moved inside the cavities.

The principle of this pumping technique is frequently misunderstood. Often it is believed to occur due to a dynamic effect caused by drag, or friction against the moving teeth of the screw rotor. In reality it is due to the sealed cavities, like a piston pump, and so has similar operational characteristics, such as being able to pump at extremely low rates, even to high pressure, revealing the effect to be purely positive displacement. The rotor “climbs” the inner cavity in an orbital manner (see pump).

people also ask

What is pump cavitation due to low flow?

In the case of suction cavitation, low-pressure or high-vacuum conditions “starve” the pump of incoming liquid, resulting in low flow. Bubbles form near the eye of the impeller, and as they move toward the discharge side of the pump, the bubbles compress into liquid and implode against the impeller’s edge.

What are the stages of a progressive cavity pump?

Pump design begins with two (to three) cavities per stage. The number of stages (currently up to 24) is only limited by the ability to machine the tooling. When the rotor is rotated, it rolls/climbs around the inside surface of the hole.

What are the limitations of a progressive cavity pump?

Due to their positive displacement, they can be sensitive to dry running if not sufficiently lubricated, leading to increased wear. Another factor is the limited pumping speed compared to other pump types such as multi screw pumps, which can make them difficult to adapt to high flow rate applications.