Overview

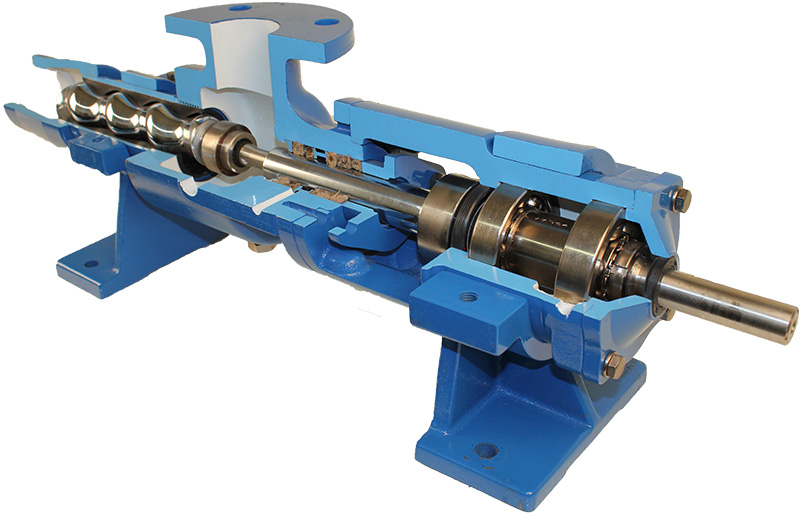

The three-screw pump is a rotor-type positive displacement pump. It uses the principle of screw meshing. The rotating screw meshes with each other in the pump sleeve, seals the medium to be transported in the meshing cavity, and pushes it to the discharge port continuously and uniformly along the axial direction of the screw to provide a stable pressure for the system.

The three-screw pump is suitable for conveying non-corrosive oils and similar oils and lubricating liquids. Progressive cavity pump viscosity range is generally 3.0-760mm²/s (1.2-100`e). High-viscosity media can be transported by heating and reducing viscosity, and the temperature generally does not exceed 150℃.

Use and scope of use

The three-screw pump is widely used in various industries such as petroleum, chemical fiber, metallurgy, machinery, electricity, machine tools, ships, glass, and roads. The three-screw pump is suitable for conveying fuel oil, lubricating oil, hydraulic oil, crude oil, asphalt and other lubricating liquids similar to oil. The three-screw pump is used as a lubricating pump in the industrial field, as a hydraulic pump in the hydraulic system, as a conveying and booster pump in the fuel system; and as a conveying and refueling pump in the oil delivery system.

Flow range 0.2~250m³/h, maximum working pressure can reach 4mpa.

Performance parameters

Maximum flow: 0.2~250m³/h

Pressure: 0~4mpa

Temperature: ≤150℃

Performance parameter difference

Single screw pump: flow can reach 150m³/h, pressure can reach 20MPa.

Twin screw pump: pressure is generally about 1.4MPa, 7MPa for viscous liquid, 3MPa for liquid with low viscosity, flow rate is 6~600m³/h, 1600m³/h, liquid viscosity shall not exceed 1500mm²/s.

Three screw pump: flow range 0.2~320m3/h, pressure is about 3.4-340kgf/cm2, flow rate can reach 18600cm3/min, viscosity can reach 50000Mpa·s, solid content can reach 50%, working temperature is 1~250°C, and special products are required if the temperature exceeds this.