How to Choose the Right Work Holding Device for 5-Axis Machining

When a shop acquires its first 5-Axis machining center, there is a lot of new information to be learned, from new and more complex programming techniques to choosing the right work holding device. These machines can tilt, rotate and position parts in ways that were not possible before, allowing you to machine five sides of a workpiece in a single setup.

This can be a challenging but straightforward exercise — providing one chooses the right work holding device.

In this month’s blog, we will explain the differences between and advantages of different types of 5-Axis work holding technology to help you make the right choice.

What is 5-Axis Machining?

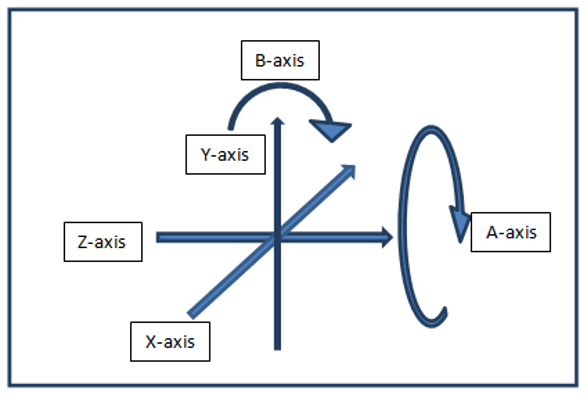

Conventional CNC machining centers operate on three axes for movement: the X-, Y- and Z-axes. In a , two of these three axes rotate, adding an A- and B-axis, as you can see represented in the picture below.

This design permits many movements at the same time to make smooth or intricate designs, and it has many benefits such as:

- Reduced number of fixtures and set-ups

- Increased accuracy;

- Reduced set-up time;

- Simplified machining of complex components.

Different Types of 5-Axis Workholding Devices

Self Centering Vise

- This system automatically adjusts the workpiece to center, which leads to improved machining precision and repeatability;

- Can be used with horizontal or vertical machinery;

- Especially beneficial to applications that require high levels of accuracy, like milling, drilling and finishing;

- More clearance angle allowing better chip evacuation;

- High holding power.

Dovetail System

- Allows multiple parts to be held by separate jaws and machined on a single centering dovetail vise;

- The locating pin makes it possible for all parts to be clamped and located the same way, which allows operators to easily load and unload the part with almost no training;

- Available in a wide range of sizes and jaw styles to clamp and hold parts of all sizes. These work holding devices can be mounted directly on a machine pallet for horizontal or vertical machining or on a tombstone;

- Decreases distortion in machined parts due to clamping forces.

Tombstones

- Also known as pedestal fixturing, tooling tower, or fixture block – tombstones typically have four sides, to which you can affix parts directly or attach various fixture plates.

Some Other Considerations

- Quick change. By using subplates and an accurate pin system, set-up changeover can be minimized;

- Systems that permit flexibility are most desirable;

- Most systems offer risers and other accessories to better enable the complete machining of the workpiece in one set-up;

- Chip clearance. Be sure that whichever design you employ, your work holding device has lots of clearance for chips to clear the workpiece.

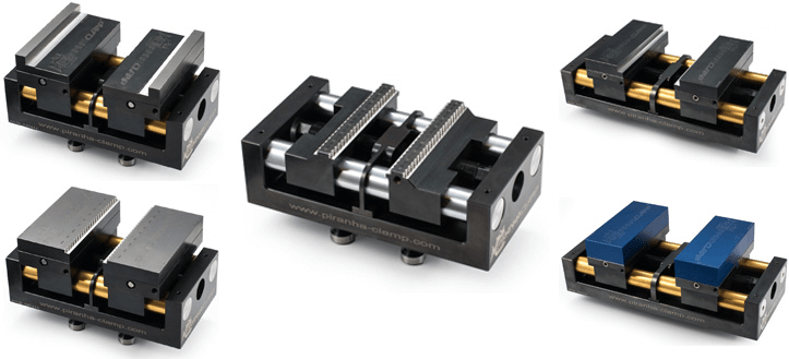

Our that offer a comprehensive range of 5-Axis work holding devices include: Jergens, Piranha Clamp, Raptor and Schunk.

Selecting the right work holding device is crucial for the success of your 5-Axis machining. For more information on each type of work holding device and its benefits, or for help selecting the right one for your shop, contact us.