Hopper pumps are essential tools in various industries, offering a range of advantages that enhance efficiency and productivity. This guide explores the benefits of using a hopper pump, highlighting its applications and features.

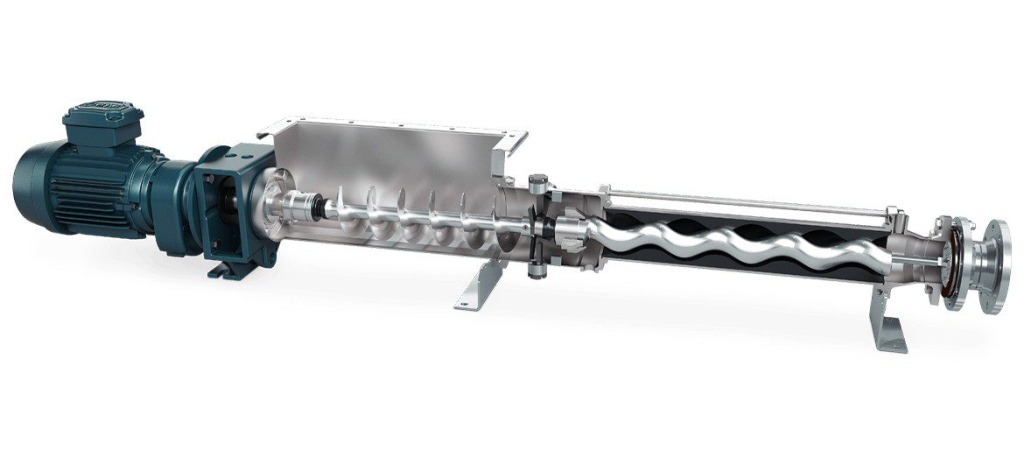

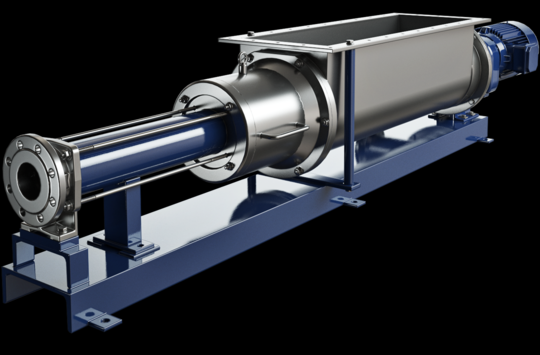

What is a Hopper Pump?

A hopper pump is designed to transport viscous materials, slurries, and other challenging substances. It typically consists of a hopper that collects the material and a pump that moves it through a pipeline. This type of pump is particularly useful in industries such as wastewater treatment, food processing, and construction.

Advantages of Hopper Pumps

1. Efficient Material Handling

Hopper pumps excel in handling materials that are thick or contain solids. Their design allows for effective transport without clogging, ensuring a smooth flow. This efficiency reduces downtime and increases overall operational productivity.

2. Versatility in Applications

These pumps can be utilized across various sectors, including:

- Wastewater Treatment: Ideal for transferring sludge and other waste materials.

- Food Industry: Suitable for moving thick sauces, pastes, and other viscous food products.

- Construction: Effective for transporting concrete mixtures and aggregates.

3. Reduced Maintenance Costs

Hopper pumps are built to withstand rigorous use, which often translates to lower maintenance requirements. Their robust construction minimizes wear and tear, thereby reducing repair costs and downtime.

4. Enhanced Safety Features

Safety is a priority in any industrial setting. Hopper pumps are designed with features that reduce the risk of spills and leaks, ensuring a safer work environment. This is particularly important when handling hazardous materials.

5. Customizable Options

Many manufacturers offer customizable hopper pumps that can be tailored to specific needs. Options such as different materials, sizes, and pumping capacities allow businesses to choose the right pump for their applications.

Key Considerations When Choosing a Hopper Pump

When selecting a hopper pump, consider the following factors to ensure optimal performance:

- Material Compatibility: Ensure the pump materials are suitable for the substances being transported.

- Pump Size: Choose a size that meets your volume requirements without overextending capacity.

- Power Source: Consider whether you’ll need an electric, hydraulic, or pneumatic pump based on your operational setup.

Conclusion

In conclusion, hopper pumps provide significant benefits that can enhance productivity, safety, and efficiency in various industries. Their ability to handle viscous materials and slurries makes them invaluable tools in modern operations. By understanding their advantages and considering key factors during selection, businesses can optimize their processes and improve overall outcomes. Investing in a reliable hopper pump can lead to long-term gains and smoother operations.