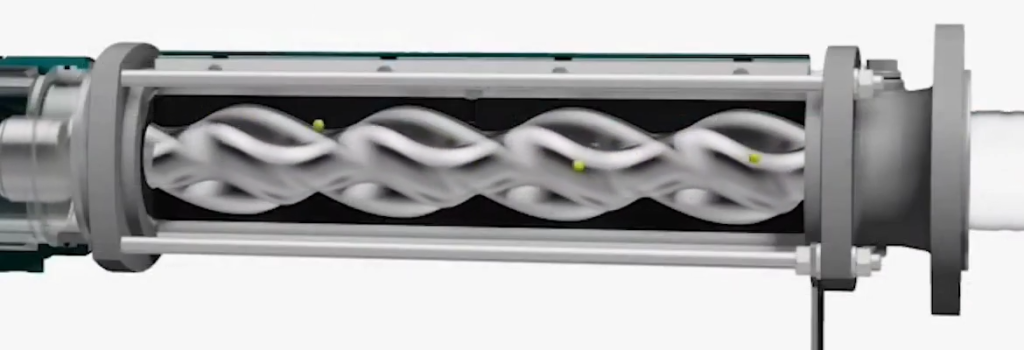

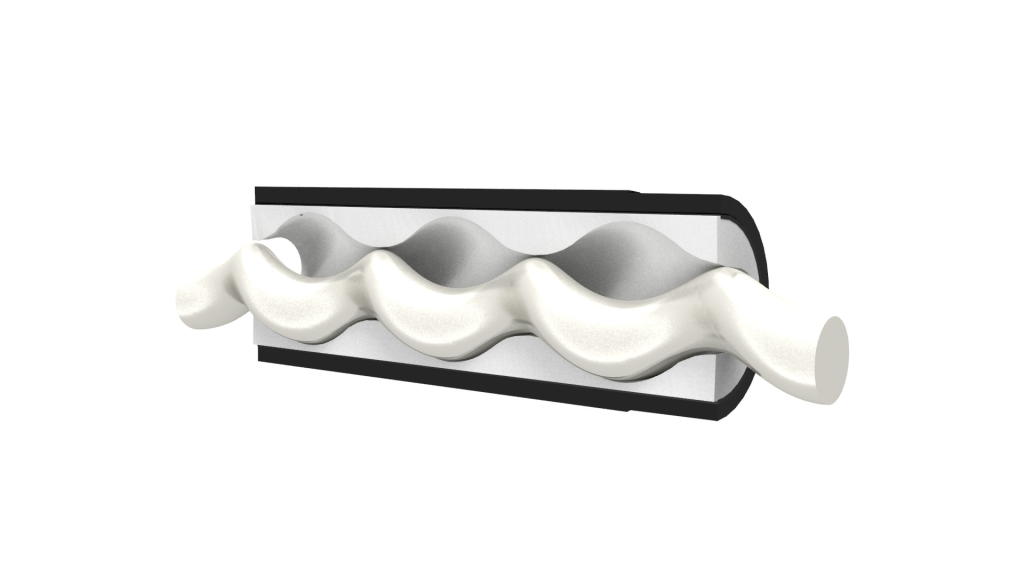

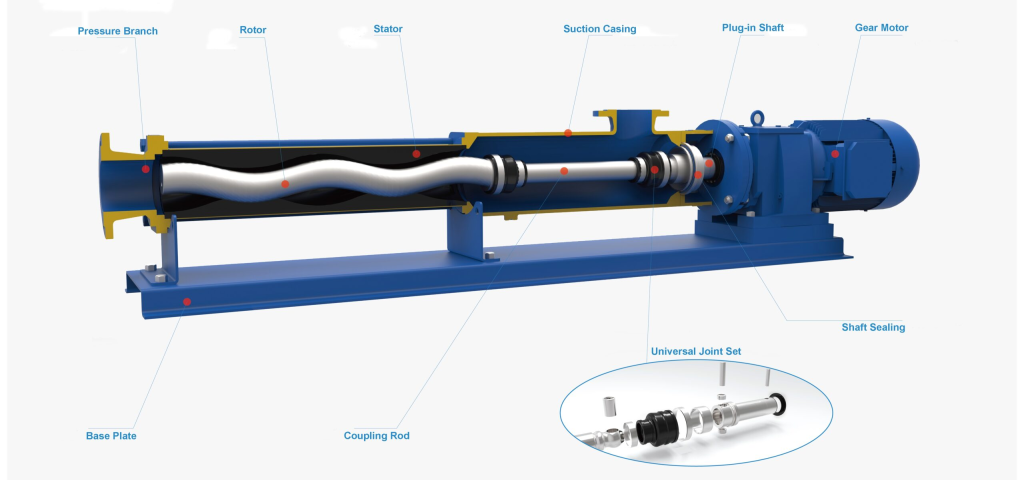

Cavity pumps, also known as progressing cavity pumps, have become an indispensable part of various industrial processes across a wide range of sectors, from oil and gas to food processing and water treatment. These versatile pumps are designed to handle a diverse array of fluids, from highly viscous to abrasive materials, making them a critical component in many applications.

As the demand for reliable and efficient pumping solutions continues to grow, it is essential to identify the top cavity pump manufacturers in the market. In this comprehensive guide, we will explore some of the leading players in the industry and their respective offerings.

- Progressing Cavity Pump Manufacturers

Progressing cavity pumps, a specific type of cavity pump, have gained widespread popularity due to their ability to handle delicate and sensitive materials without compromising their integrity. Several manufacturers have established themselves as leaders in this segment.

One such industry leader is Seepex, a German-based company with a global presence. Seepex’s progressing cavity pumps are renowned for their robust design, energy-efficiency, and versatility, making them a preferred choice in a variety of industries, including oil and gas, food and beverage, and water treatment.

Another prominent player in the progressing cavity pump market is Netzsch, a German manufacturer with a rich history spanning over a century. Netzsch’s pumps are known for their exceptional performance, high reliability, and advanced technological features, making them a go-to solution for complex pumping applications.

Prominent progressing cavity pump manufacturers:

- Seepex

- Netzsch

- Sulzer

- Xylem

- Weatherford

- Mono

- Cavity Pump Applications and Industries

Cavity pumps, including progressing cavity pumps, find applications in a wide range of industries, each with its unique requirements and challenges. Some of the key industries that rely on these pumps include:

Oil and Gas: Cavity pumps are extensively used in the oil and gas industry for the transfer of crude oil, lubricants, and a variety of other viscous fluids.

Water and Wastewater Treatment: These pumps play a crucial role in the handling of sludge, slurries, and other difficult-to-pump materials in water and wastewater treatment facilities.

Food and Beverage: Cavity pumps are well-suited for the gentle and efficient transfer of delicate food and beverage products, such as sauces, pastes, and suspensions, without compromising their quality.

Mining and Minerals: In the mining and minerals industry, cavity pumps are employed for the handling of abrasive and erosive slurries, ensuring reliable and continuous operation.

Chemicals and Pharmaceuticals: Cavity pumps are utilized in the chemical and pharmaceutical industries for the transport of a wide range of chemicals, solvents, and other specialized fluids.

- Key Factors to Consider when Selecting Cavity Pump Manufacturers

When choosing a cavity pump manufacturer, there are several critical factors to consider to ensure the best fit for your specific application:

Pump Performance: Evaluate the pump’s capacity, flow rate, pressure capabilities, and overall efficiency to ensure it meets your operational requirements.

Material Compatibility: Ensure that the pump’s construction materials are compatible with the fluids you will be handling, minimizing the risk of corrosion or wear.

Energy Efficiency: Look for manufacturers that offer energy-efficient pump designs, which can lead to significant cost savings over the pump’s lifetime.

Reliability and Durability: Choose a manufacturer with a reputation for producing high-quality, long-lasting pumps that can withstand the demands of your industry.

Customer Support: Consider the level of technical support and after-sales service provided by the manufacturer, as this can be crucial for maintaining optimal pump performance and troubleshooting any issues that may arise.

By carefully evaluating these factors, you can ensure that you select the most suitable cavity pump manufacturer for your specific needs, ultimately leading to improved efficiency, reduced maintenance costs, and enhanced overall performance.