#145 – Tyco’s New LFP Antifreeze Meets NFPA Listing Requirements

Tyco LFP is the first listed antifreeze since flammability concerns caused a phase-out of antifreeze in fire sprinkler systems

As the 2022 deadline for phasing out all current antifreeze solutions in wet sprinkler systems looms, the first – and only – product to meet the National Fire Protection Association’s (NFPA) latest standard offers a new possibility to keep wet sprinkler systems functional in frigid climates.

In December, Johnson Controls launched Tyco LFP™ Antifreeze, a third-party tested and evaluated solution that stands as the only UL-certified antifreeze for fire sprinkler systems as of February 2019.

It emerges a decade after incidents where antifreeze released from sprinklers ignited, prompting NFPA to issue guidance that limits its use to older systems and phases out every antifreeze product already on the market by 2022. Without this new solution, antifreeze could no longer be used in sprinkler systems after the sunset date – potentially rendering existing systems that depend on it useless and forcing property owners to turn to costlier ways to prevent pipes from freezing.

In this blog, QRFS reveals why current solutions were deemed unsafe, details about the new antifreeze solution, where it can be used, and how it helps fire sprinkler systems meet NFPA standards.

The danger posed by flammable antifreeze in fire sprinkler systems

While preaction or dry sprinkler systems are commonly used in areas that are subject to freezing temperatures, wet sprinkler systems that rely on antifreeze have also long served as a viable option for protecting areas exposed to cold.

Ice crystals begin to form in fresh water at 40 F (4.4 C), creating the potential for wet systems to malfunction or suffer leaky or burst pipes. In a traditional antifreeze system, water mixed with either propylene glycol or glycerin at specific ratios flows throughout the pipes to keep the water from freezing.

Here’s the problem: propylene glycol and glycerin are flammable substances that can easily catch fire at high concentrations. Before NFPA mandated the exclusive use of factory premixed solutions, people could easily mix the proportions incorrectly.

And even if they are mixed properly, there’s no guarantee that they will stay that way: gravity can cause the components of antifreeze solutions to separate over time. If an unsafe ratio of the active ingredient is concentrated in the area near a sprinkler when it discharges, the spray may become deadly fuel for the fire.

The worst proof of this alarming risk grabbed headlines in 2010 when a woman was killed and the rest of her family was injured after an explosion in their apartment. Investigators later discovered that their apartment’s fire sprinkler system had poured antifreeze with a dangerously high proportion of glycerin – reportedly a whopping 71.2 percent concentration – onto a grease fire, triggering the blast.

What NFPA requires for antifreeze solutions

On the heels of this tragedy and a previous incident, the NFPA issued Tentative Interim Amendments to quickly block the use of antifreeze in new automatic residential sprinkler systems. Since 2013, new versions of NFPA 13: Standard for the Installation of Sprinkler Systems, NFPA 13R: Standard for the Installation of Sprinkler Systems in Low-Rise Residential Occupancies, and NFPA 13D: Standard for the Installation of Sprinkler Systems in One- and Two-Family Dwellings and Manufactured Homes all require the use of listed solutions in all new systems.

From the 2019 Edition of NFPA 13

8.6.2.1* Except as permitted in 8.6.2.2, antifreeze solutions shall be listed for use in sprinkler systems.

Solutions that are “listed” have been safety-tested and approved for use in automatic sprinkler systems. Antifreeze solutions are tested and certified to UL 2901, which evaluates such factors as fire performance, solution stability, the effect when exposed to certain materials associated with sprinkler systems, and human health and environmental impact.

Section 8.6.2.2 of NFPA 13 addresses the exception: certain Early Suppression, Fast Response (ESFR) systems may use premixed antifreeze solutions of propylene glycol in certain listed applications. ESFRs are high-output sprinkler systems intended for use in warehouses with “high piled storage” that are notoriously difficult to climate control.

Premixed antifreeze solutions that are not listed can also be employed in certain older sprinkler systems until the sunset date. But their use is strictly governed by NFPA 25: Standard for the Inspection, Testing, and Maintenance of Water-Based Fire Protection Systems, which limits them to very specific maximum ratios of active antifreeze ingredients to water:

From the 2017 edition of NFPA 25

5.3.3.4.1* For systems installed prior to September 30, 2012, listed antifreeze solutions shall not be required until September 30, 2022, where one of the following conditions is met:

(1) * The concentration of the antifreeze solution shall be limited to 30 percent propylene glycol by volume or 38 percent glycerine by volume.

(2) * Antifreeze systems with concentrations in excess of 30 percent but not more than 40 percent propylene glycol by volume and 38 percent but not more than 50 percent glycerine by volume shall be permitted based upon an approved deterministic risk assessment prepared by a qualified person approved by the authority having jurisdiction.

But read this carefully: Maintenance requirements to continue using these solutions are often prohibitively complex, as they involve periodically taking samples from different points in the system to assess the ratio of water to the flammable ingredient.

NFPA also emphasizes that antifreeze solutions with these low concentrations of propylene glycol and glycerin might not provide sufficient freeze protection for sprinkler pipes. Don’t place total confidence in premixed antifreeze solutions that are marketed as “compliant with NFPA requirements.” That only means that the solution is of a type, chemical purity, and concentration that fits the various standards – and not that it is listed for use in newer fire sprinkler systems.

From the 2019 edition of NFPA 13

3.3.160 Premixed Antifreeze Solution. A mixture of an antifreeze material with water that is prepared and factory mixed by the manufacturer with a quality control procedure in place that ensures that the antifreeze solution remains homogeneous and that the concentration is as specified.

From the 2017 edition of NFPA 25

5.3.3.4.2 Newly introduced solutions shall be factory premixed antifreeze solutions (chemically pure or United States Pharmacopeia 96.5 percent).

The new option: What you need to know about Tyco LFP Antifreeze

As the first listed antifreeze solution to hit the market since concerns about flammability arose, Tyco’s LFP Antifreeze may enable property owners to install new wet systems and continue using existing ones for residential, commercial, and some storage applications in freezing environments. Tyco says that the product ensures fast and effective flow in wet sprinklers exposed to cold temperatures while protecting both metallic and thermoplastic piping against damage from freezing.

For residential use, that typically means vacation homes, attics, breezeways, balconies, and garages. Common commercial uses are parking garages, garden centers, loading docks, and temporary protection for buildings under construction.

That said: LFP Antifreeze is not approved for every situation. It’s essential to note that it’s not listed for use in ESFR sprinklers or for protecting extra hazard occupancies or spaces with flammable liquids.

NFPA 13 (3.3.134) defines extra hazard occupancies as “occupancies or portions of other occupancies where the quantity and combustibility of contents are very high and dust, lint, or other materials are present, introducing the probability of rapidly developing fires with high rates of heat release but with little or no combustible or flammable liquids.” They are also “occupancies or portions of other occupancies with moderate to substantial amounts of flammable or combustible liquids or occupancies where shielding of combustibles is extensive.”

Fire protection industry leader Johnson Controls developed LFP Antifreeze to meet the requirements of UL 2901 for compliance with the 2019 editions of NFPA 13, 13R, and 13D, as well as the 2017 edition of NFPA 25.

It reports that the premixed solution remains in a liquid state at temperatures as low as –10 F (-23.3°C). When sprinklers are activated during a fire event, the mix of active ingredients and water is immediately discharged from the sprinkler head – eliminating the up to 60-second delivery delay of dry sprinkler systems, another cold-weather alternative.

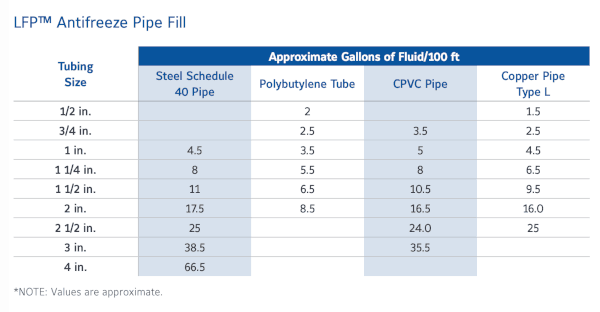

LFP Antifreeze is suitable for use with most common piping system materials (for a complete list, click here). That includes chlorinated polyvinyl chloride (CPVC), a popular choice for both residential systems and demanding industrial applications because it has high resistance to corrosion, heat, and pressure.

Per environmental standards, the solution can be simply disposed of through normal sewer or septic systems – if permitted by local laws – or at wastewater treatment centers.

Some details about LFP Antifreeze:

- Appearance: liquid, colorless

- UL-certified/listed

- FBC system-compatible. This means it is tested – and monitored on an ongoing basis – to assure its chemical compatibility with FlowGuard Gold, BlazeMaster, and Corzan pipes and fittings.

- Minimum use temperature: -10 F. The freeze point when crystallization begins is –13 F.

- Maximum use temperature: 150 F

- Density at 77 F: 9.4 lbs./gal

- pH: 7-8

- Conductivity: 1000—1400 µS/cm

- Safe handling procedures: The solution was formulated to reduce risks to humans and the environment. Nevertheless, gloves and eye protection are recommended when handling LFP Antifreeze.

Special considerations:

- LFP Antifreeze is factory premixed to meet NFPA standards. Diluting it with water or anything else will adversely impact its properties and performance.

- End-use environmental conditions can impact the functional life of the solution. It should be stored between 40 F and 90 F and not placed in anything other than the original container, as others may introduce contaminants.

- LFP Antifreeze should only be used in closed systems, so oxygen can’t contribute to an increased rate of pipe corrosion.

LFP Antifreeze offers a future for wet systems that rely on antifreeze in cold climates

Fire sprinkler systems are the first line of defense in fire protection – and it’s essential to ensure they are working properly before fires break out. As temperatures plummet, failing to protect wet sprinkler piping from freezing puts people and property at risk.

LFP Antifreeze is the only product on the market that fulfills the NFPA’s mandate to use listed solutions in new fire sprinkler systems. And as the deadline for phasing out all other antifreeze products from existing systems fast approaches, it may wind up being the only solution deemed safe and stable enough to use in wet sprinkler systems – unless another manufacturer successfully lists a new product.

If you have any questions about the use of antifreeze in fire sprinklers or need help finding any item for your system, give QRFS a call at 888.361.6662 or email support@qrfs.com.