- Previous blog

- Next blog

- Huyett Marketing Department

- 01/27/2022

Pipe plugs are threaded plugs that seal the ends of pipes to prevent the flow of fluids. They are used in industries ranging from domestic plumbing and construction to hydraulics, gas and oil transportation, agriculture, food and beverage manufacturing, and industrial chemical processing. In short, wherever there are pipes, you’ll find pipe plugs.

As you might expect from such a common part, pipe plugs come in many different designs and sizes — at Huyett,

we offer over 1,300 variations — which can make it challenging to select the best pipe plug for your application.

we offer over 1,300 variations — which can make it challenging to select the best pipe plug for your application.

How Do Pipe Plugs Work?

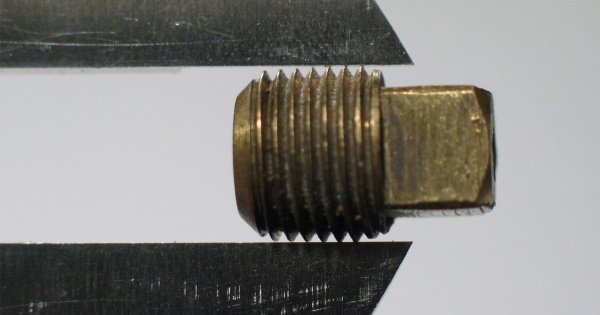

Pipe plugs are cylindrical metal fittings with a taper‑threaded shaft at one end and a drive section at the other. Tapered threads have a slight cone profile, causing the male and female threads to compress against each other to form a tight seal. In use, the male threaded shaft is screwed into the female thread of a pipe or housing. The primary role of a pipe plug is to block the flow of fluids, but they are also used to prevent dirt and other contaminants from entering an opening in a pipe.

Before we get to the details, we should mention that the term “pipe plug” also refers to inflatable pneumatic pipe sealers used to block the flow of fluids in large pipelines, often for leak testing and maintenance. However, this article discusses threaded metal pipe plugs rather than inflatable or expandable pipe plugs.

Pipe Plugs vs. Pipe Caps

Pipe plugs have male threads and are screwed internally into the end of a pipe. In contrast, pipe caps have female threads and are screwed onto the outside of the pipe.

Pipe plugs and pipe caps perform the same function; however, pipe plugs can be used in locations where it’s not feasible to put a cap over a pipe’s end. For example, pipe plugs can be used to close an opening in the side of a larger pipe or the wall of a machine housing.

Pipe Plugs vs. Drain Plugs

Pipe plugs and drain plugs are similar products, but they differ in the specification of their threads. Pipe plugs have National Pipe Taper Fuel (NPTF) threads, whereas drain plugs have PTF‑SAE Short threads, also known as PTF threads. Both threads are tapered to resist leaking; however, PTF‑SAE threads have one full thread less than NPTF threads, allowing for a lower profile. Drain plugs are often used in applications where clearance of moving parts is a consideration.

When Should You Use A Threaded Pipe Plug?

Threaded pipe plugs are suitable for most applications in which plumbers need to end‑stop a pipe. They are convenient, durable, and easy to install and remove with widely available tools. However, pipe plugs require an internally threaded pipe, which may not always be available.

Alternatives to threaded pipe plugs include threaded pipe caps, as we’ve already discussed. Where threads are not available, plumbers often solder unthreaded caps, particularly on domestic copper piping. In industrial plumbing scenarios with large pipes, butt welded or socket welded pipe caps may be used instead of threaded plugs. Correctly welded caps are very strong, but they are permanent and require special equipment to install.

How to Measure Pipe Fittings

Selecting a pipe plug of the correct size can be challenging because of inconsistencies in the pipe thread size designations and pipe plug sizes. It is not possible to find the correct pipe plug size by simply measuring the outside or inside diameter of the pipe and selecting a matching part.

To find the correct pipe plug for your pipe, measure the pipe’s inside diameter. Then, use a thread chart to determine the thread’s nominal size. Find the measured thread diameter on the chart and then the equivalent nominal size.

Read

Pipe Thread Basics to learn more.

Pipe Thread Basics to learn more.

How to Choose a Pipe Plug

There are six main factors to consider when choosing a pipe plug: the thread size, thread type, drive type, standard specifications, material, and finish. On Huyett pipe plug product pages, you will find descriptions such as:

Plug, Pipe 1/8‑27 NPTF, Hex Socket, SAE J531, Low Carbon Steel, Plain

This represents everything you need to know when selecting a pipe plug.

Thread Size and Thread Type

After the product type — pipe plug or drain plug, for example — you will see the thread size and type. In the example above, the thread size and type are “1/8‑27 NPTF.”

- 1/8 is the thread size, as explained in the previous section.

- 27 indicates the thread pitch — the distance between crests. The thread pitch is determined by its size and type.

- NPTF indicates the thread type. The most common thread types are NPTF and PTF‑SAE, but we also stock British Standard Pipe Taper (BSPT) pipe plugs.

Reference the chart below for an explanation of the most common pipe thread types:

Pipe Plug Drive Types

Pipe plugs have a screw drive on the end opposite the threads. The drive mates with appropriately shaped tools to allow the plug to be screwed into position. Pipe plug screw drives are available in many types and sizes suitable for different tools and situations. In our example, the drive type is ”

Hex Socket,” a six‑point socket that mates with a tool fitted with a standard hex bit.

Hex Socket,” a six‑point socket that mates with a tool fitted with a standard hex bit.

Other common drive types include:

- Square head pipe plugs

- Square socket pipe plugs

- Hex head pipe plugs

- Slotted pipe plugs

- Six lobe pipe plugs

Each of these is available in a range of thread sizes, allowing plumbers to select the thread size and drive type to suit their project.

Pipe Plug Standards

Following the drive type, you will see a standard designation. In the example, it’s “SAE J531.” SAE is the Society of Automotive Engineers — this pipe plug is commonly used in the automotive industry. Pipe plug standards define the plug’s specifications. SAE J531 defines dimensional specifications for square and hexagon pipe and drain plugs.

The specifications are helpful if you need a full breakdown of a pipe plug’s dimensions, including its body length, body width, head length, head height, and more.

Other common pipe plug standards include:

- ASME B16.11

- ASME B16.14

- DIN 906/158

- JIS D2101

Read

Characteristics of Pipe Plugs to learn more about pipe plug standards.

Characteristics of Pipe Plugs to learn more about pipe plug standards.

Pipe Plug Materials

Pipe plugs are manufactured in several types of metal because they are used in many different applications with pipes made of many different materials. When choosing a pipe plug, select one made of the same material as the pipe or one made of a material with desirable properties.

Commonly used materials include:

- Low carbon steel

, which is hard and durable enough for most low‑pressure applications. The example pipe plug is made of low carbon steel. - Stainless steel

is a strong and corrosion‑resistant metal comprising iron, carbon, and varying quantities of chromium. - Alloy steels

are available in many different varieties. They are harder and more durable than low carbon steel. - Aluminum

is ideal for use with aluminum pipes and where lower weights are a priority. However, uncoated aluminum may corrode more quickly in the presence of other metals, including iron and brass. It is also weaker than steel and should not be used in high‑pressure environments. - Brass

is an alloy of zinc and copper. It is widely used in plumbing fasteners. Brass is malleable, highly resistant to corrosion, and suitable for moderately high temperature environments such as hot water pipes.

Pipe Plug Finishes

The final section of the product description is the finish, which adds a protective layer. Our example has a “Plain” finish, which means nothing has been added to the metal surface.

Other finish options include:

- Passivated

, a finish used for stainless steel pipe plugs and drain plugs. The steel is exposed to an acid, which causes the formation of a corrosion resistant oxide layer. - Black oxide

, a conversion coating process that forms a corrosion‑resistant coating of magnetite (Fe3O4), which may then be impregnated with oil or wax. - Zinc trivalent

, a passivation finish for zinc‑plated pipe plugs and drain plugs. The passivation process creates a corrosion‑resistant chromate layer that, depending on the specific process used, gives the finish a clear, gold, black, or green color.

Where to Buy Pipe Plugs and Drain Plugs

Huyett stocks a comprehensive selection of pipe plugs in all sizes, thread types, drive types, materials, and finishes mentioned here, and many others we haven’t discussed. View our

full selection of pipe and drain plugs or contact our

knowledgeable and friendly Sales team.

full selection of pipe and drain plugs or contact our

knowledgeable and friendly Sales team.