Progressive Cavity Adhesives and Liquids Pump: The Unsung Heroes of Industrial Applications

In modern industry, many critical processes and equipment rely on a relatively unsung but key component – the progressive cavity adhesives and liquids pump. This unique pump design not only plays an important role in various industrial applications, but it is also driving continuous progress and innovation in these industries.

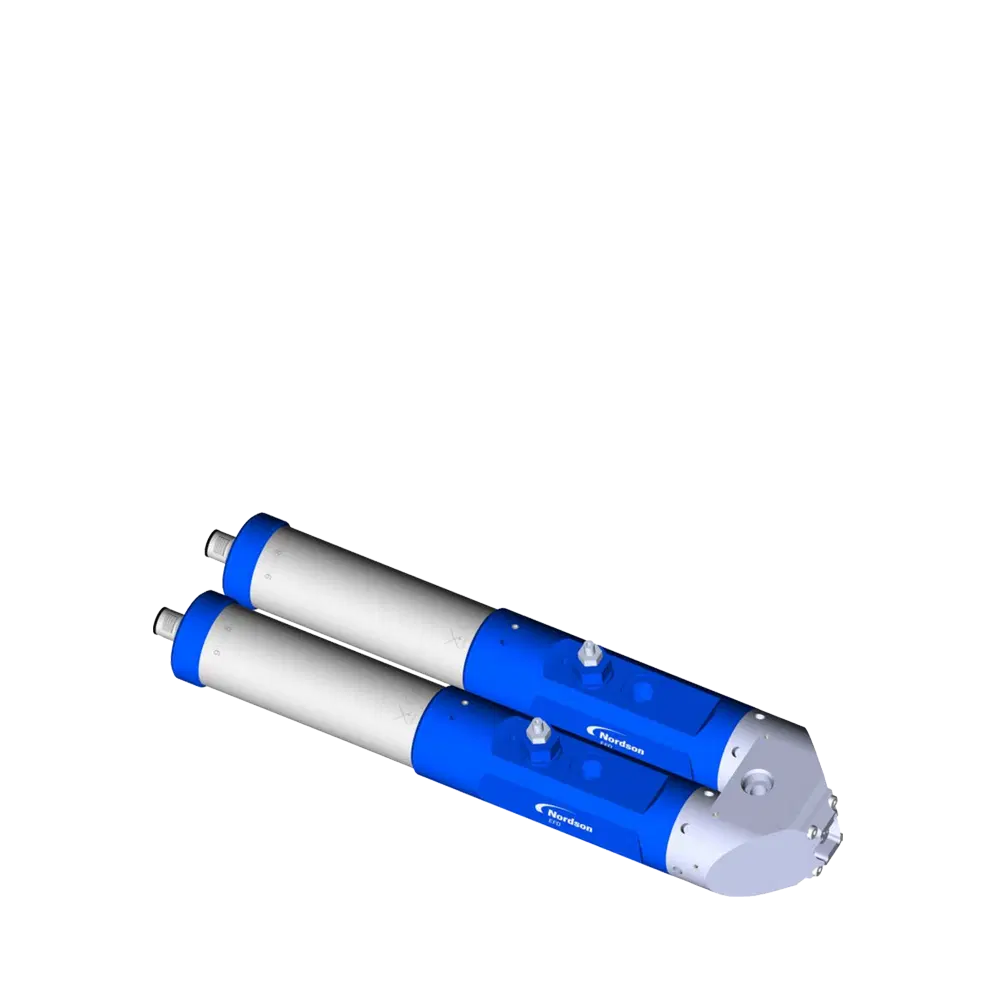

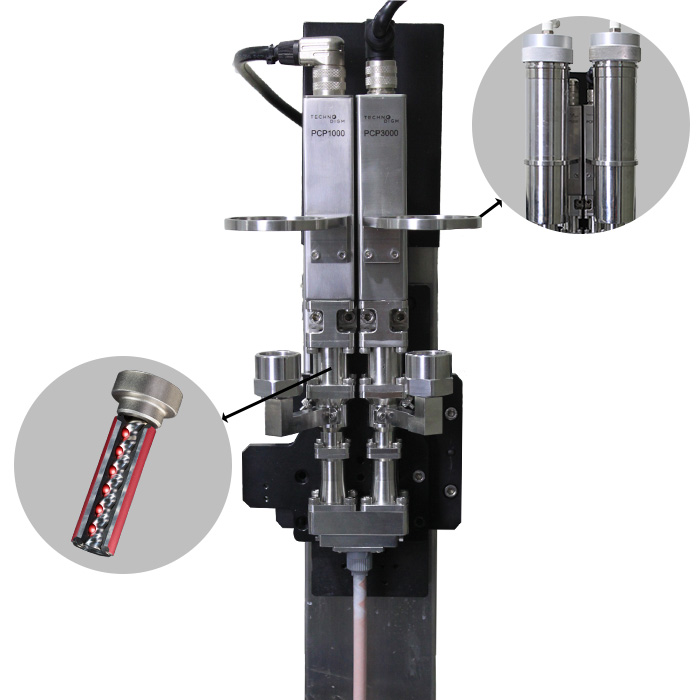

Progressive cavity adhesives and liquids pumps are primarily used to transport a variety of viscous fluids, such as chemical feedstocks, food and pharmaceutical preparations, and industrial lubricants. Unlike traditional centrifugal or gear pumps, progressive cavity pumps utilize a unique helical rotor and stator structure that can smoothly convey high-viscosity, shear-sensitive materials without pulsation. This gives them a distinct advantage when handling leak-prone, temperature-sensitive fluids.

In addition to superior pumping performance, progressive cavity pumps are also known for their durability and ease of maintenance. Their compact design and few wear parts significantly reduce operating costs and downtime. Moreover, through judicious material selection, these pumps can also offer excellent corrosion resistance in harsh industrial environments. These attributes make them indispensable in many process applications.

From food processing to cosmetics manufacturing, from pharmaceuticals to petrochemicals, progressive cavity adhesives and liquids pump can leverage their unique strengths. In the pharmaceutical industry, they are widely employed for transporting a variety of high-viscosity liquids, such as capsule fillings, pastes, and ointments. In the food sector, they reliably handle viscous syrups, condiments, and fruit preserves. In the chemical domain, they excel at pumping corrosive chemicals and polymer emulsions.

As industry continues to evolve, progressive cavity pumps are also undergoing constant improvement and innovation. The application of new materials, the integration of smart control systems, and other advancements are further expanding the versatility of these pumps. Looking ahead, we can expect progressive cavity adhesives and liquids pumps to play an even more pivotal role, becoming the unsung heroes that drive progress across a wide range of industrial fields.