Q: What lengths of steel do I need for my guide rail build to achieve my desired rip capacity?

I’m getting ready to buy my steel for making my own guide rails and I’m also in the middle of making an extension table at the same time. How do I make sure I don’t buy too much or not enough steel? And, do you have any tips for buying steel?

~ Adam A.

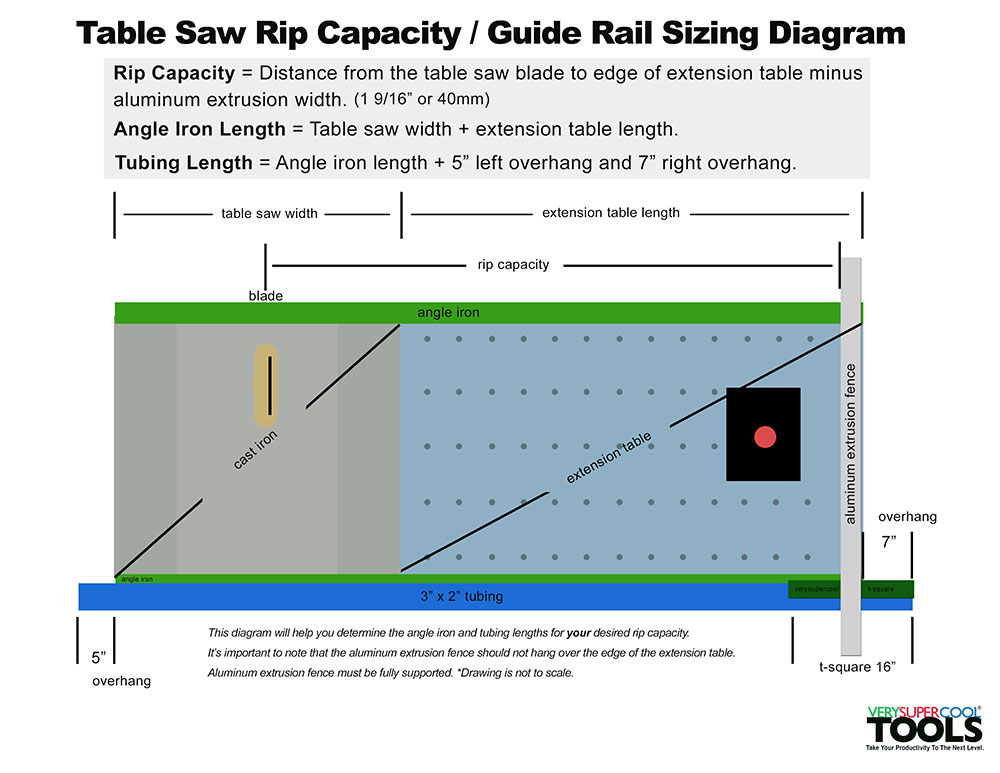

A: After you have determined your desired rip capacity, use the diagram below to calculate your angle iron and tubing lengths.

It’s easy to figure out how much steel to buy. You just need a few calculations. It’s always better if you can visualize what you are doing, that’s why I made the diagram below. You can click on the button or click on the diagram itself to download the pdf.

- Rip Capacity = Distance from the table saw blade to edge of extension table minus aluminum extrusion width. (Our extrusions are 1 9/16″ or 40mm)

- Angle Iron Length = Table saw width + extension table length.

- Tubing Length = Angle iron length + 5” left overhang and 7” right overhang.

Regarding buying your steel, many steel places will sell you drops, you just need to ask them. Where I frequently buy steel they have what they call a “Drop Zone” where odds and ends are available. But I think buying full length pieces is always the most cost effective way to buy steel. You may end up with extra, but if you’re like me, you can always find a use for pieces steel. And if not, just watch my Welding for Woodworkers series on YouTube, and you will quickly find some other uses for steel in your shop too.

~ Allan Little, AskWoodMan

Download Guide Rail Sizing Diagram