- Previous blog

- Next blog

- Huyett Marketing Department

- 04/15/2021

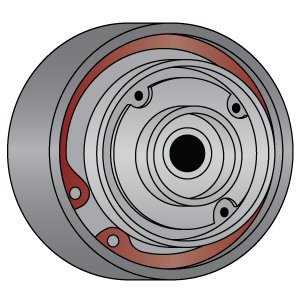

Significant effort and consideration goes into determining the right retaining ring for a given application while the groove in which the retaining ring is seated is rarely given a second thought. The design of a retaining ring groove is the most effective method for reducing the likelihood of retaining ring failure.

Why Retaining Ring Grooves are Important

Retaining rings are only as good as the groove in which they are installed. If the groove does not properly seat the fastened retaining ring, then the assembly’s capacity will be less than the rated capacity of the retaining ring. The groove is often overlooked when designing assemblies held together by a retaining ring. Thoughtful consideration when designing the groove can increase thrust load capacity and reduce the likelihood of assembly failure.

What Causes Retaining Rings to Fail?

The most common cause for retaining ring failure is groove material deformation. When groove material is softer than the retaining ring and axial forces exceed compressive yield strength of both the retaining ring and the groove material, the groove profile deforms. When this happens, the retaining ring is unable to seat perpendicular in the groove, substantially decreasing the thrust load capacity of the fastened assembly. The deformed groove causes the retaining ring to tilt and work its way out of the groove when under load.

What Design Factors Reduce Risk of Retaining Ring Groove Deformation?

Some design factors to consider when machining retaining ring grooves include groove location, groove material, and groove profile.

Groove Location

Retaining ring grooves are, more often than not, located toward the end of a shaft or bore. This is usually to accommodate the installation and removal of radially installed retaining rings. It is more important not to locate the groove too close to the end of the shaft as risk of shearing from excess forces is increased. Edge margin, or the distance between the edge of the shaft or bore to the groove, should be approximately three times the groove depth.

Groove Material

Groove material is an important facet of groove design. The yield strength of different materials plays a significant role in the amount of thrust load capacity an assembly can withstand. Stronger materials like 8620 hardened steel feature a yield strength of 110,000 psi, whereas softer, cast iron has a yield strength up to 40,000 psi. Since groove material deformation is a common cause for retaining ring failure, it is important to understand the yield strengths of the materials used and ensure suitability for the intended application.

Groove Profile

A groove profile should have a near exact rectangular cross section and be shaped so that a retaining ring can almost completely fill the space. While having sharp corners is often the most desired outcome, variations in tooling do not always allow this. Retaining ring manufacturers provide minimum and maximum groove radii for a given retaining ring. In addition to corners, groove width and depth should also be evaluated.

How wide should a snap ring groove be?

Groove width minimum should always be slightly larger than maximum ring thickness, but not more than a few thousandths of an inch. When a ring is properly seated in a groove, some axial tolerance will exist, allowing for slight dishing when load is applied. It is important to note that while slight dishing is acceptable, excessive dishing can cause a retaining ring to deform permanently or fracture.

How deep should a snap ring groove be?

The depth of the groove ring determines how much of the retaining ring extends beyond the groove. If the groove is too shallow, a lever‑arm effect occurs where axial forces can cause dishing of the retaining ring resulting in premature failure of an assembly. As a general rule of thumb, groove depth should be about one‑third the radius of the retaining ring.

And There You Have It!

It is critical to give retaining ring grooves their due. Considering groove design when evaluating assembly requirements could significantly reduce the likelihood of failure. If you are looking for more information about retaining ring applications, visit our

product FAQs page or

contact our expert Sales team today!

product FAQs page or

contact our expert Sales team today!

Want a copy of the Huyett Housing and Snap Ring Size Chart Guide?

Enter your email below to get your FREE download and sign up for our newsletter.