- Previous blog

- Next blog

- Huyett Marketing Department

- 03/25/2021

- Updated 01/11/2024

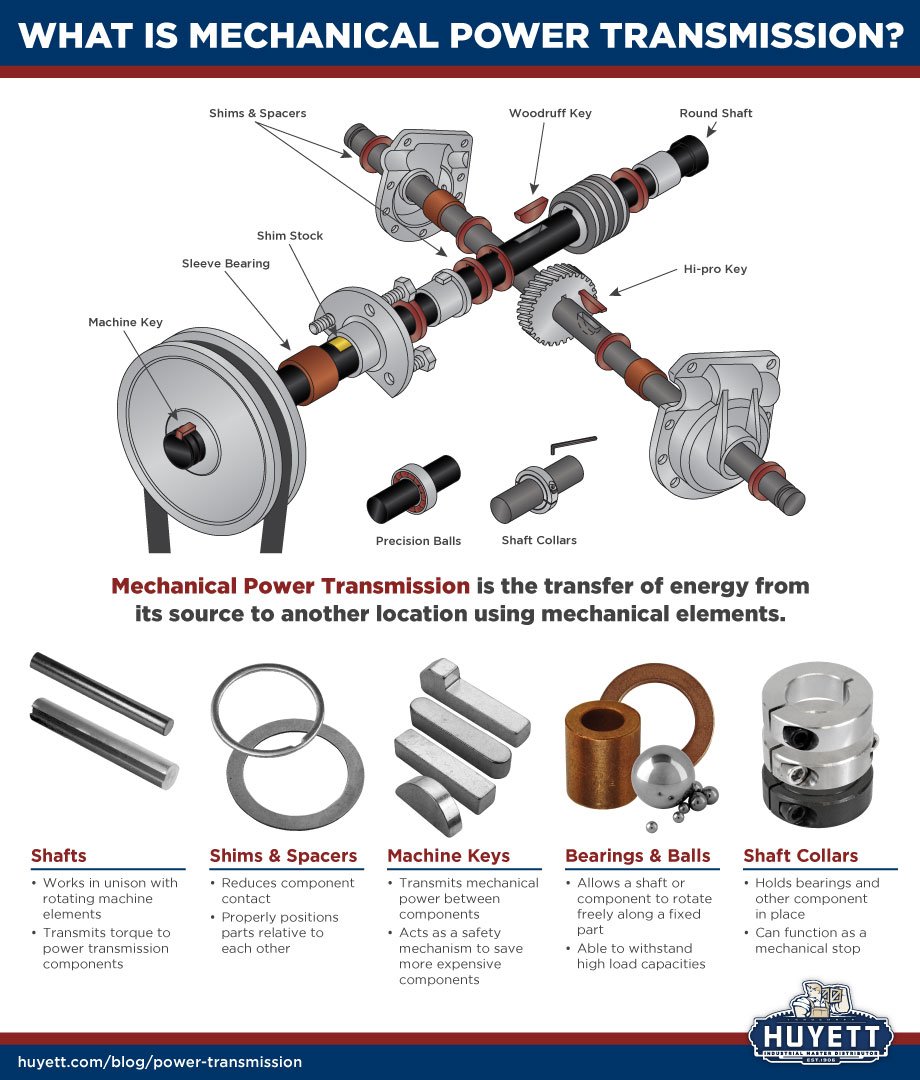

In its simplest form, mechanical power transmission is the transfer of energy from one place to another where it is then put to work. This transfer of power is a system of integrating gears and shafts that provide speed and torque conversion.

We often use mechanical power—the energy within a mechanical system—some distance from where it is generated. An internal combustion engine converts chemical energy into mechanical energy, but to do useful work it must be transmitted to a vehicle’s wheels by a series of shafts, gears, and bearings.

Mechanical power transmission is just one of several methods engineers use to get power to where it’s needed, but it is an essential aspect of most machines, from intricate mechanical watches to the

largest machines ever made by human beings.

largest machines ever made by human beings.

Electrical power transmission has replaced mechanical power transmission in many modern scenarios—we rarely transmit mechanical power over large distances, as was once common. Instead, we use generators to convert mechanical power to electricity, transmit it over wires or store it in batteries, and convert it back into mechanical power in another location.

But machines that rely on electrical power transmission also use mechanical power transmission to get energy from where it’s generated to where it’s used—a Tesla doesn’t have an internal combustion engine but it still uses shafts and bearings to transmit power to its wheels.

What is a Mechanical Power Transmission System?

A mechanical power transmission system is a system of linkages and power transmission elements. Its primary role is sending power to a location in which it does useful work. It may also change the power’s direction, speed, or torque; power transmissions often convert the reciprocal movement of pistons into the rotary movement of an axle or use a system of transmission gears to adjust torque and speed.

Mechanical power is transferred through a number of different mechanisms, including the following:

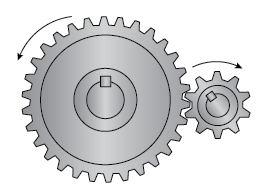

Gears:

Adjacent, interlocked gears rotate at different speeds in opposite directions, with the smaller gear rotating more quickly.

Adjacent, interlocked gears rotate at different speeds in opposite directions, with the smaller gear rotating more quickly.

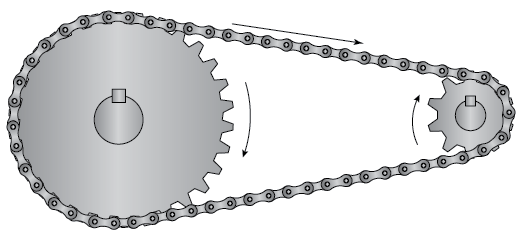

Sprockets:

Sprockets are profiled wheels that connect with a chain or track. They differ from gears in that they do not touch. In this configuration, both sprockets turn in the same direction as the chain that connects them.

Sprockets are profiled wheels that connect with a chain or track. They differ from gears in that they do not touch. In this configuration, both sprockets turn in the same direction as the chain that connects them.

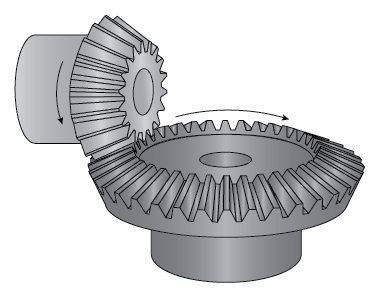

Special Configurations:

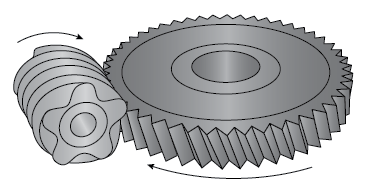

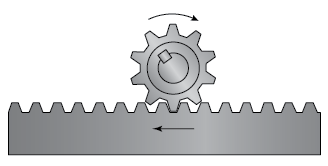

Special gear and sprocket configurations including spur gears, worm drives, helical gears, beveled and mitered gears, and rack and pinion gears are used to transfer power from one axis to another.

Special gear and sprocket configurations including spur gears, worm drives, helical gears, beveled and mitered gears, and rack and pinion gears are used to transfer power from one axis to another.

Machines take advantage of many different systems to get power where it’s needed, including gear drives, shaft couplings, belt drives, and chain drives, each of which is composed of interlinked power transmission components.

What are Power Transmission Components?

Power transmission components are the individual elements that make up a power transmission system. They either transmit mechanical power or facilitate its transmission by other components. There are thousands of varieties with different specifications, designs, roles, and materials. Let’s have a look at a few of the mechanical power transmission components offered by Huyett.

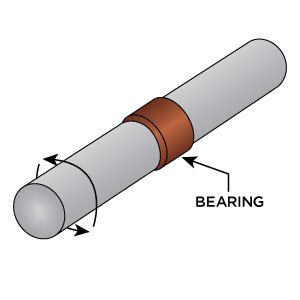

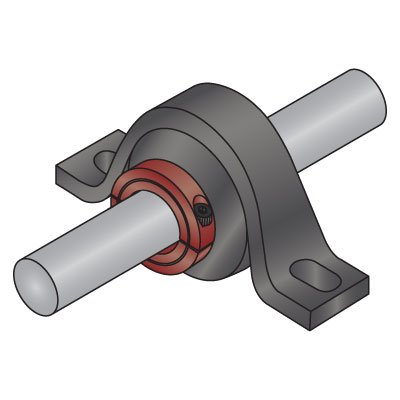

Power Transmission Bearings

Power transmission

Shaft collars support rotating shafts and constrain their motion to a single vector or plane. For example, a bearing might allow a shaft to rotate freely while preventing it from moving side‑to‑side within its housing.

Shaft collars support rotating shafts and constrain their motion to a single vector or plane. For example, a bearing might allow a shaft to rotate freely while preventing it from moving side‑to‑side within its housing.

Bearings are often designed to reduce friction between two parts; ball bearings use smooth balls and races to achieve reduced friction and plain bearings are often oil‑infused to facilitate the free motion of rods and shafts.

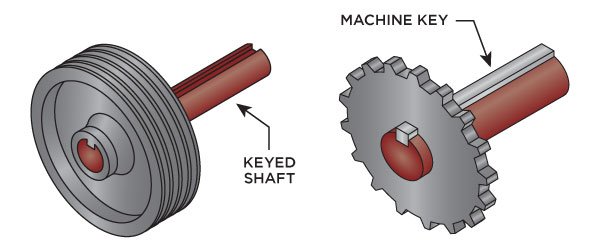

Machine Keys and Keyed Shafts

A shaft is a rotating component, usually circular, that transmits mechanical power between machine components. Shafts can be simple lengths of rod, or they might be more complex components such as crankshafts. Shafts connect to the other components in a machine by various mechanisms, but one of the most common is the

machine key.

machine key.

A machine key transmits mechanical power between the shaft and a rotating component such as a gear. It fits into a slot on both components, ensuring that they cannot move relative to each other. We offer many types of

keyed shafts, machine keys, and

key stock.

keyed shafts, machine keys, and

key stock.

In normal operation, a keyed assembly allows primary gears and drive shafts to turn together. However, if forces exceed design limits, the machine key may shear, preventing damage to other components. Inexpensive machine keys effectively act as safety stops to protect expensive mechanical components.

Machine Shaft Collars

Shaft collars are circular components that clamp around the diameter of a shaft. They are among the most widely used machine components and they have many applications, including holding bearings and other components in place and acting as a stop to prevent shaft movement.

Shaft collars are available with several different clamping mechanisms.

Set shaft collars use a set screw to apply force directly to the shaft, whereas

single split and

double split shaft collars have openings at each side that are closed by screws.

Set shaft collars use a set screw to apply force directly to the shaft, whereas

single split and

double split shaft collars have openings at each side that are closed by screws.

More about Power Transmission Hardware

To learn more, take a look at our full

guide to power transmission hardware. In addition to standard hardware, we also manufacture custom components, including custom machine keys and key stock.

Contact a member of our Sales team for more details.

guide to power transmission hardware. In addition to standard hardware, we also manufacture custom components, including custom machine keys and key stock.

Contact a member of our Sales team for more details.